So, once I got some setups out of the way, I got some time to spend with the Telecaster re-fret job.

We left off with the board clean and level with clean, straight fret slots. I also had to order some fret wire with a tang width larger than any I had in stock.

Now we can get to the nitty gritty….putting some frets in!

When a fret board is straight and level the first thing I need to do is radius and cut the fret wire to length…

…as you can see from the photo, the fret wire is cut with a fair bit of over-hang and is given a radius slightly tighter than that of the board. This is for two reasons 1) it keeps tension across the fret to keep the fret ends down and 2) as the fret is driven into the slot, the barbs at the ends of the tang will be driven downwards AND sideways into the fret slot wall, resulting in a more secure fit. This picture shows a fret with too much radius in it though, I had to flatten it out a tad…if you radius a fret too much you run the risk of the centre of the fret popping up…not cool!!

As I cut and radius the frets one by one I store them in my little numbered fret block so I know which fret goes where…

..I know it probably looks like overkill but if I don’t do this and get them mixed up it really will ruin my day!

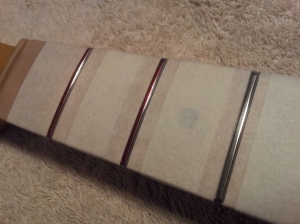

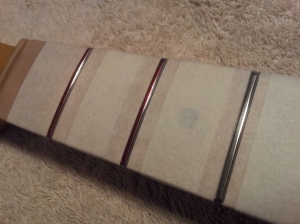

After all frets are given a radius and cut to length, I will set them out in their respective slots to double-check lengths and radius. This is worth doing as you don’t want to realise you’ve made a cock-up in the middle of hammering frets in…trust me!!!

So once I have all my frets ready, it’s time to put ’em in!!

Now, at this stage it’s worth mentioning some different methods for fitting frets. The three most common methods are hammering, pressing and gluing. These methods are not exclusive of each other however. Methods can be mixed to better suit the requirements of specific guitars. I have, at some point, used all of these methods and mixtures of them to get a job done. Sometimes it is necessary to use more than one method on different areas of the same neck.

The hammer method is the oldest and most traditional method of fretting a guitar. The fret is offered up to the slot and is driven in by a few precision “dead” blows of a fretting hammer. The fret is held in place by the interference fit of the tang and its barbs against the wall of the fret slot. The exact level of interference is determined by the tech/luthier to influence bow in the neck….this is compression fretting as mentioned previously.

The pressing method is similar to the hammering method except the fret is “pushed” into interference using a machine press fitted with a concave caul that matches the radius of the fretboard.

The gluing method involves using a slightly undersized tang or widening the fret slot so the fret can be pushed into its slot by hand. Glue is applied to the fret slot or run across the tang and the fret is clamped in position until dry.

It’s worth noting that for a brief period of time Fender used a method to fit frets where the wire was driven into the slot from the side using a shuttle on a pulley. To my knowledge no manufacturer is using this method anymore. However if I do a re-fret on a guitar from this period I will always remove the frets sideways as removing them from the top will tear the board to shreds!

Of the all the methods mentioned above I prefer to use the hammer and glue methods, often mixing both together depending on the job. I don’t really like the pressing method as I feel you lose some of the control you have using your hands to feel the feedback of the neck. I’ve seen people use the press to great effect and it does work….I just don’t like it.

On this particular re-fret we know we have nice big fret slots and we know I now have wire with a matching tang, so for this job I will use a hammer to seat the frets and sure things up with a drop of glue.

Over the years luthiers and techs have been arguing about the use of glue in fret slots. I think it is perfectly fine. Not only does the glue make sure the fret does not pop up in the future, and trust me they can, it also fills air gaps in the fret slot making for a more positive mechanical contact for the fret. This positive contact actually helps sustain and reduces dead spots in the neck. Removal is no problem as the fret is always heated,breaking any glue bond. Be aware that we are not glueing the metal to the wood, we are using the glue to reduce any clearance inside the fret slot giving it a nice snug fit and no way to wobble or spring out.

Once I’ve offered up the fret to the slot I hold it in place with one hand and make one light strike on one end followed by a sharp, slightly harder dead blow to seat it. Then I do the same to the opposite side. I then do the same dead centre and finish with six light dead blows along the length of the fret at all string positions…

I do the same in every fret position, stopping only to check that the fret is correctly seated…not proud of the board and not “sunk” into the fretboard.

Once I am happy that all frets are seated correctly, i clamp the neck very lightly, side up and add 2-3 drops of water-thin cyanoacrylate(CA) super glue into the end of the fret slot using the protruding fret-end as a drip feeding wick. I let the neck sit for 30 seconds then spin it and do the same to the other side, again leaving it for 30 seconds or more….you really don’t want CA to run out of the slot and onto the finish….you will be doing a lot of scraping, filing, sanding and polishing! As we are relying on capillary action to “suck” the glue into the fret slot,some glue will naturally want to run down the side of the fret bead across the fretboard…no big problem there, we just need to tidy that up before we say we are done!

Time for a cup of tea/coffee while the glue cures and the neck settles down!

Once I’m happy the glue is cured (most CA’s cure in 30-60 seconds) and the neck has settled, it’s time to sort out the fret ends.

When cutting back the fret ends before dressing, we need to use pretty butch cutters for the job. Fret wire is, generally, very soft nickel/silver so it can be cut with standard electrical side cutters, but, if you struggle or stall during a cut you risk bending the fret or wiggling it out of position. For this task we need to make one quick, economical “snip”. When we cut the fret we do it as close to the board without marking at and in a downward motion, away from the fretboard surface so as to not pull the fret out at its end.You have seated and glued the frets, if you distort them in any way now you are in a whole world of pain! So for this job I have a dedicated pair of industrial cantilever cutters…..tug, snip, done, tug, snip…

…..now the frets are seated and glued we need to cut the frets back to the width of the neck. There are a few ways of doing this but here’s how I do it…

I put the neck in my soft-jaw vice with the fretboard facing me and take my medium cut engineers bastard file and GENTLY start filing each fret-end at a time ON THE FORWARD STROKE ONLY! This is because A) the file only cuts on the push stroke anyway and B) if i pull at the fret with the file I could bend the end slightly causing it to become unseated…not good!

I keep going, carefully, until i am flush with the fretboard edge, sometimes, as I’m approaching flush I switch to a fine double-cut file to feather the fret-end right up to the edge of the board…

…once the frets are completely flush with the fretboard it means the fret ends are now at sharp right angles to it….not very comfortable to play on! So it’s time to add a bevel to the edge of the frets.

Different manufacturers, luthiers and techs have differing ways of doing this. Some manufacturers like Gibson bevel the edge of their frets at a very acute angle with steep “shoulders”. Fender guitars have a far more relaxed bevel and very soft “shoulders”

The angle of bevel can be anything you like really but somewhere between 30 and 45 degrees is the accepted “norm”.

You can buy files which have wood or nylon “runners” with mill files embedded in them to give you a uniform bevel along the board but here’s my thinking…

If you want to give different boards different bevel angles you need to buy more than one of these ridiculously expensive files and if you can’t put a uniform bevel into frets by hand then you are really going to struggle with fret dressing! A craftsman uses his hands and his skill!

I have a very fine-cut mill file set into a wooden handle that I use to bevel frets. I simply offer the file up to the fretboard edge, tilt it to my desired bevel angle then use my left hand and my right hand fingers as “rails” feeling the neck as I file to keep the bevel angle uniform. That’s how it was done back in the day and that’s how I like it done!

…you can see that this fret has been beveled now, the file obviously leaves a pretty raw bevel so this will need to be “softened” to make playing more comfortable…this is fret dressing.

The first step of dressing the fret is to “knock away” the sharp right angle at the base of the fret bead left by levelling/beveling the ends. To do this i use a fine-cut four-sided file with one side ground “safe”. This side rests on the board and the file is rolled around both edges of the fret bead to knock away that horrible right angle and leave a nice, rounded fret end.

(NOTE – At this point we would apply at least a sealer coat of lacquer to the fretboard if not the entire lacquer finish. However i thought i would go ahead and show the dressing, leveling and crowning process in one hit. I will shoot the board with lacquer in the next post then re-crown/polish frets where necessary.)

Due to the slight inconsistencies of the extruded fret wire and the fact that some frets can seat very slightly lower than others we have to do some leveling…usually not a lot but it needs to be done so we know we are spot on!

Since all work has been carried out methodically and accurately we know we wont need to hump off a lot of metal so, usually, we can just “kiss” the fret tops with some sand paper on a radius block or leveling beam if we were working on a compound radius…

I tape off the fretboard and run the radius block the entire length of the board with a few passes and stop to see how level the frets are using an engineers straight-edge and a fret-rocker. Once i am happy that we are level along the entire length of the board it’s at this point we might think about adding “fall-away” to the frets.

To explain the point of “fall-away” we need to know something about guitar necks. Long, solid objects, such as guitar necks don’t tend to change much along their length providing they are not put under any stress or pressure from a source outside of their own construction. When a guitar neck is glued or bolted to a body compressive forces act on the body-join area of the neck. This compressive force can “bulge” a neck at the body join position causing a slight rise in the fret board. This bulge can stay in the neck even when there is no string tension and when the neck is removed. This can be taken out of the board when we level the surface of the board but it doesn’t hurt to add some measure to stop notes “fretting-ou” in the future when string tension is applied and the neck settles. Fall-away is slightly tapering the frets from the body join fret (14th-ish) to the last fret. The disparity from the 14th fret to the last only needs to be a few thousands of an inch to make an appreciable difference and a slightly raised action from 14th to last fret is not felt.

One way i add fall-away is by shimming the 14th fret with several layers of tape so that a leveling beam will rest on this raised area adding a taper to the frets in the upper register. Half of the levelling beam is covered with tape to stop it eating into the taped shim-stock and the beam is run over these frets with a couple of passes. Progress can be checked with a straight edge and some feeler gauges…

…as you can see from the photo I have added machinists ink to the top of the frets so I can see how much material is being removed as I level and add fall-away.

Once we are happy that we are all level I give the frets a polish using 400/600/800/1000 and 1200 grit papers…we’re not done yet but the polished surface makes the next task a little easier.

The leveling process has left us with slight flat spots on our fret tops. These flat areas not only increase drag on the underside of the string, making bending feel “gritty” but the large contact area with the string makes intonation less accurate. We need to establish a fine point of contact at the top of the fret for the string…we call this the crown…so this is fret crowning.

There are a few ways to approach re-crowning frets, most methods fall into two catagories…crowning using a purpose made,concave file and hand crowning using a straight file.

The concave files are just that, file handles with file burrs that are concave to suit the desired crown or fret size. These usually come in two different types, coarse cut toothed files and multi directional cut diamond files.These files usually have interchangeable burrs to suit different fret wire types. These files eat into the fret top and wear the corners of the flat spots into sloped shoulders until a crown is present.

Hand crowning employs a flat file, usually a three side file with corners ground safe. The file is gently pushed along the length of the fret and rolled-over at the same time. This process is carried out on both sides of the fret, switching every so often to roll the fret shoulders to centre.

Although I do own, and occasionally use, a concave burr file i don’t like it and nearly all of my fret work is completed using the traditional hand crowning technique.

The problem with concave files is that you basically have no fine control. The file will just mindlessly “eat” the fret away at a rate determined by the cut on the file surface. You also have no control over the final crown dimension as this is governed by the radius of the file. They also tend to leave more scratches and “chatter” marks than hand filing. One of the things that really pisses me off about them is that all fret wire you ever crown HAS to fall within the dimension boundaries of three types of burrs only. Obviously this isn’t always the case and many fret wire dimensions can be outside of these burr sizes, When this happens you to eat into the shoulder of the fret with the file or bottom out at the tip of the crown meaning you have to level again as you have compromised your level surface…….infuriating!

So I’m afraid this thing sits on my work bench and only sees the light of day for rush jobs that have certain, definite fret wire sizes like tall vintage and medium jumbo..rant over!

So we keep the board taped up in case we slip, and we do all slip, and we paint the flat tops with machinists ink. As I said we gentle push the file across the side of the fret and gently roll it up the side of the fret, softly curving the shoulder of the fret sides to centre until there is a perfectly straight, razor-thin line of flat “datum” surface for the string to contact…

…this is a long process and shouldn’t be rushed, the results, if executed correctly, will be a super smooth feeling fret with super accurate intonation.

Once all fret tops are rounded to centre and perfectly crowned we polish, again, with 400/600/800/1000 and 1200 grit paper, then fine grade wire wool and finally automotive polishing compound to leave the fret perfectly smooth and shining like brand new caddy chrome!

At this point we are moving closer to re-finishing the fret-board but that will be part 3 of this job! I will be going through the steps for lacquering our finished board with nitrocellulose!

Stay tuned!

TFM